1. Ka maloʻo ʻana o ka naylon PA66

ʻO ka hoʻomaloʻo ʻana i ka momi:mahana ℃ 95-105 manawa 6-8 hola

Hoʻomaloʻo ea wela:ka mahana ℃ 90-100 manawa ma kahi o 4 mau hola.

Crystallinity:Koe wale no ka nylon transparent, ʻo ka hapa nui o nā nylons he crystalline polymers me ka crystallinity kiʻekiʻe. Hoʻomaikaʻi ʻia ka ikaika tensile, ke kūpaʻa ʻana, ka paʻakikī, ka lubricity a me nā waiwai ʻē aʻe o nā huahana, a ke emi nei ka hoʻonui ʻana o ka wela a me ka hoʻoheheʻe wai, akā ʻaʻole kūpono ia i ka ʻike a me ka pale ʻana i ka hopena. He hopena nui ka wela o ka mold i ka crystallization. ʻO ke kiʻekiʻe o ka mahana o ka mold, ʻoi aku ka kiʻekiʻe o ka crystallinity. ʻO ka haʻahaʻa o ka mahana mold, ʻoi aku ka haʻahaʻa o ka crystallinity.

Hoʻemi:E like me nā plastics crystalline ʻē aʻe, he pilikia nui ka emi ʻana o ka resin nylon. ʻO ka maʻamau, pili loa ka emi ʻana o ka nylon i ka crystallization. Ke loaʻa ke kiʻekiʻe o ka crystallinity o ka huahana, e hoʻonui ʻia ka emi ʻana o ka huahana. ʻO ka hoʻohaʻahaʻaʻana i ka mahana wela, ka hoʻonuiʻana i ke kaomi injection, a me ka hoʻohaʻahaʻaʻana i ka mahana o ka mea i ka wā o ke kaʻina hana e hoʻemi ai i ka hoʻohaʻahaʻaʻana, akā, e piʻi aʻe ka pilikia o loko o ka huahana a maʻalahi ka hoʻololi. ʻO ka emi ʻana o PA66 he 1.5-2%

Nā lako hana: I ka wā e hoʻoheheʻe ai i ka nylon, e hoʻolohe i ka pale ʻana i ka "mea hoʻolei ʻana o ka nozzle", no laila hoʻohana mau ʻia nā nozzles paʻa ponoʻī no ka hana ʻana i nā mea nylon.

2. Nā huahana a me nā poni

- 1. ʻO ka mānoanoa o ka pā o ka huahana ʻO ka lōʻihi kahe o ka nylon ma waena o 150-200. ʻAʻole liʻiliʻi ka mānoanoa pā o nā huahana nylon ma mua o 0.8mm a koho ʻia ma waena o 1-3.2mm. Eia kekahi, pili ka emi ʻana o ka huahana i ka mānoanoa pā o ka huahana. ʻO ka mānoanoa o ka pā, ʻoi aku ka nui o ka emi ʻana.

- 2. Exhaust ʻO ka waiwai nui o ka resin nylon ma kahi o 0.03mm, no laila pono e hoʻomalu ʻia ka lua o ka lua ma lalo o 0.025.

- 3. Mold wela: Hoʻomaʻamaʻa a hoʻomaluʻia nā'ōmole me nā paia lahilahi i paʻakikī e hoʻoheheʻe aiʻole e koi ana i ka crystallinity kiʻekiʻe. Hoʻohana maʻamau ka wai anuanu no ka mālama ʻana i ka mahana inā makemake ka huahana i kahi pae o ka maʻalahi.

3. Kaʻina hana hoʻoheheʻe nylon

Ka wela o ka barela

No ka mea, he polymer crystalline ka nylon, he wahi hehee nui kona. ʻO ka mahana o ka pahu i koho ʻia no ka resin nylon i ka wā o ka hoʻoheheʻe ʻana e pili ana i ka hana o ka resin ponoʻī, nā mea hana, a me ke ʻano o ka huahana. ʻO ka Nylon 66 he 260°C. Ma muli o ka maikaʻi ʻole o ka wela o ka nylon, ʻaʻole kūpono ka noho ʻana i loko o ka pahu i ka wela kiʻekiʻe no ka manawa lōʻihi e pale aku i ka discoloration a me ka melemele o ka mea. I ka manawa like, ma muli o ka wai maikaʻi o ka nylon, kahe wikiwiki ia ma hope o ka ʻoi aku o ka mahana ma mua o kona helu heheʻe.

Paʻi hoʻoinu

He haʻahaʻa ka viscosity o ka nylon melt a maikaʻi ka wai, akā wikiwiki ka wikiwiki condensation. He maʻalahi ka loaʻa ʻole o nā pilikia i nā huahana me nā ʻano paʻakikī a me nā paia lahilahi, no laila ke koi ʻia nei ke kaomi injection kiʻekiʻe.

ʻO ka maʻamau, inā kiʻekiʻe ke kaomi, e loaʻa i ka huahana nā pilikia overflow; inā haʻahaʻa loa ke kaomi, loaʻa nā hemahema e like me ka ripples, bubbles, sintering marks a i ʻole nā huahana lawa ʻole. ʻAʻole ʻoi aku ka nui o ke kaomi ʻana o nā ʻano nylon ma mua o 120MPA. ʻO ka maʻamau, koho ʻia i loko o ka laulā o 60-100MPA e hoʻokō i nā koi o ka hapa nui o nā huahana. ʻOiai ʻaʻohe hemahema o ka huahana e like me nā ʻōpū a me nā niho, ʻaʻole makemake ʻia ka hoʻohana ʻana i ke kaomi paʻa kiʻekiʻe e pale aku ai i ka hoʻonui ʻana i ke kaumaha o loko o ka huahana. ʻOi aku ka wikiwiki o ka injection No ka nylon, ʻoi aku ka wikiwiki o ka injection, hiki iā ia ke pale i nā ripples a me ka lawa ʻole o ka hoʻopiha piha ʻana ma muli o ka wikiwiki hoʻomaha. ʻAʻohe hopena koʻikoʻi o ka wikiwiki injection wikiwiki i ka hana o ka huahana.

Ka wela mold

Loaʻa i ka mahana o ka mold kekahi mana i ka crystallinity a me ka molding shrinkage. He kiʻekiʻe ka crystallinity, ka paʻakikī, ka elastic modulus, ka hoʻemi ʻana i ka wai, a me ka hoʻonui ʻana i ka hoʻoheheʻe ʻana o ka huahana; ʻO ka wela haʻahaʻa haʻahaʻa he crystallinity haʻahaʻa, paʻakikī maikaʻi, a me ka elongation kiʻekiʻe.

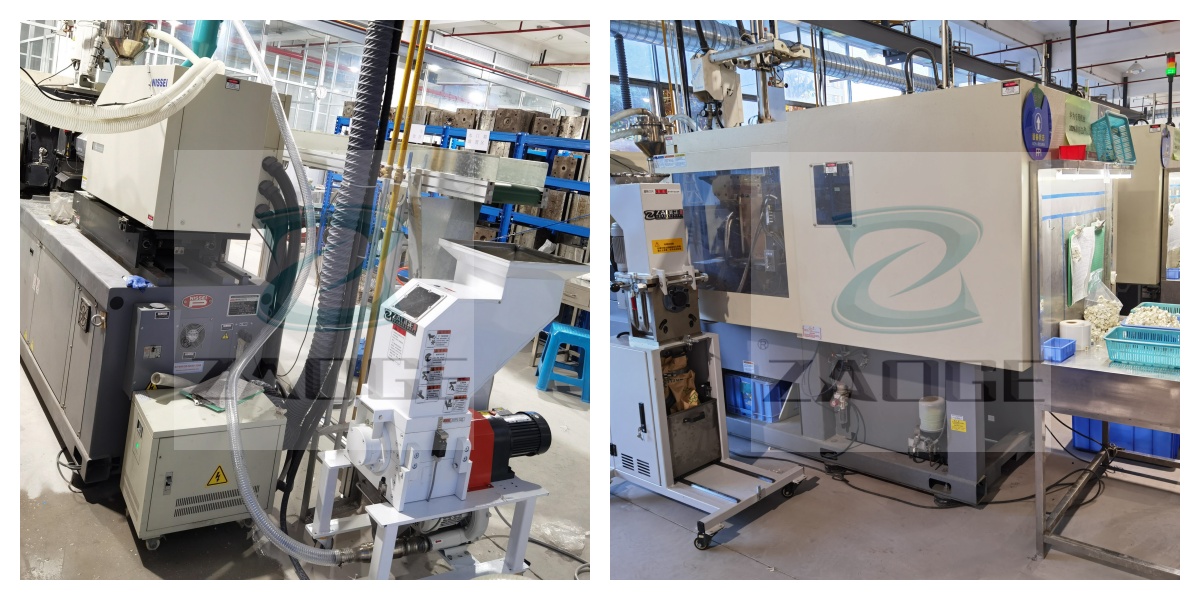

Hoʻopuka nā papa hana hoʻoheheʻe i nā sprues a me nā kukini i kēlā me kēia lā, no laila pehea e hiki ai iā mākou ke hana hou i nā sprues a me nā mea holo i hana ʻia e nā mīkini hoʻoheheʻe injection?

Waiho iaʻO ZAOGE palekana kaiapuni a me nā mea kākoʻo mālama waiwai (plastic crusher)no nā mīkini hoʻoheheʻe ʻia.

ʻO ia kahi ʻōnaehana wela a hoʻohana hou ʻia i hoʻolālā ʻia e wāwahi i nā sprues a me nā mea holo kiʻekiʻe.

Hoʻihoʻi koke ʻia nā ʻāpana maʻemaʻe a maloʻo i ka laina hana e hana koke i nā huahana Injection molded parts.

Hoʻololi ʻia nā ʻāpana maloʻo maʻemaʻe a maloʻo i nā kumu waiwai kiʻekiʻe no ka hoʻohana ʻana ma mua o ka hoʻohaʻahaʻa ʻana.

Hoʻopakele ia i nā mea maka a me ke kālā a hiki ke hoʻokele maikaʻi i ke kumukūʻai.

Ka manawa hoʻouna: Iulai-24-2024